Simulate and analyze

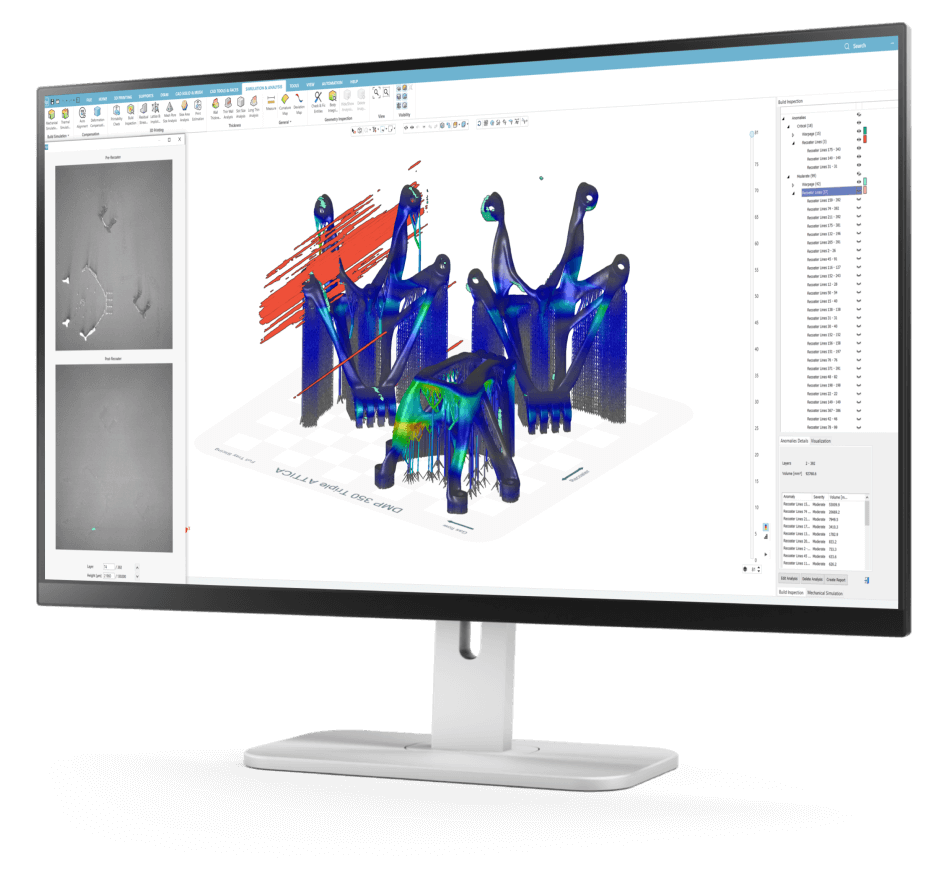

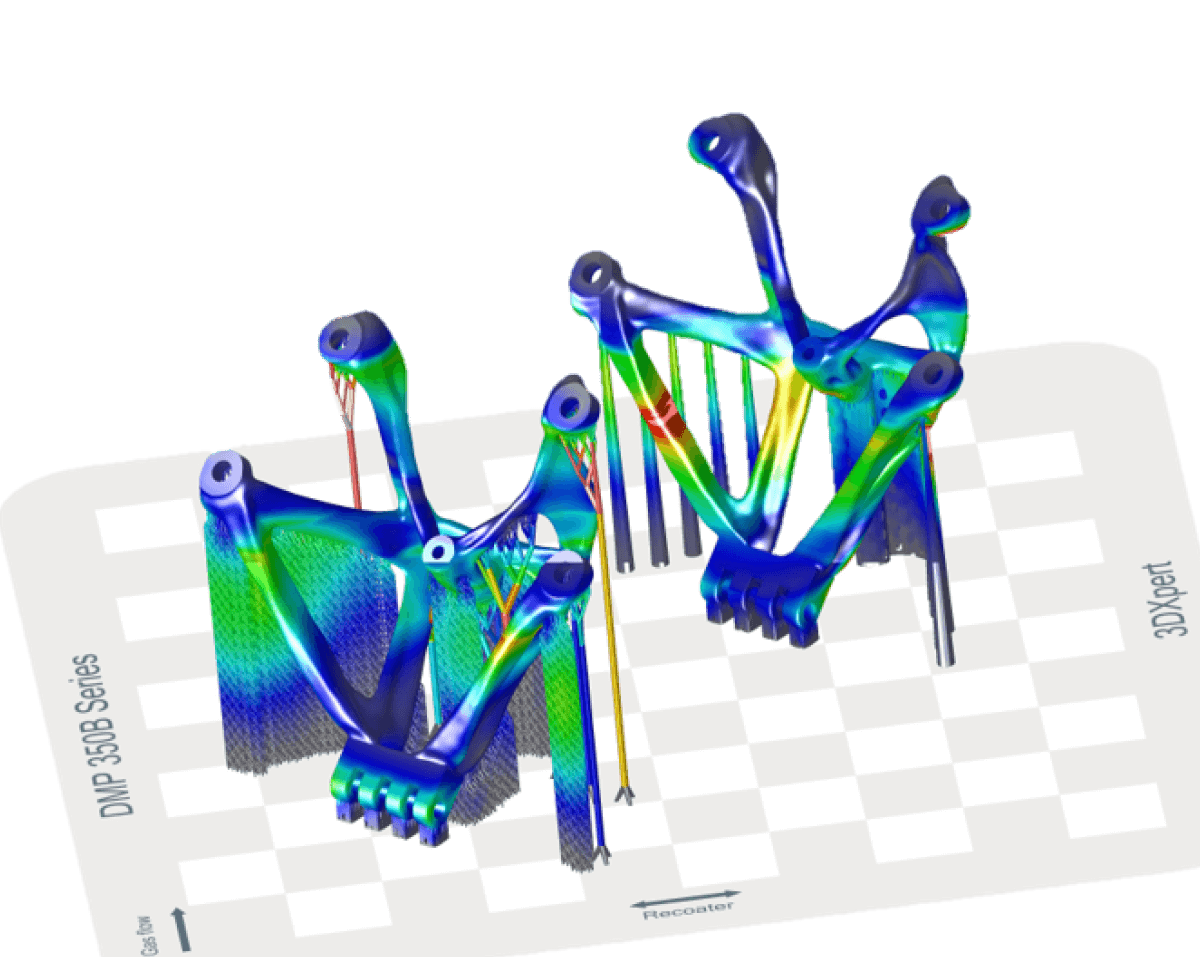

Simulate and analyze for deformations, shrinklines, plastic deformations, thermal performance and more with 3DXpert Build Simulation.

Produce quality parts with confidence. Our AI-powered solution monitors, tracks and inspects your quality metrics for metal powder bed builds. Get real-time insights to your additive manufacturing process with Oqton Build Quality.

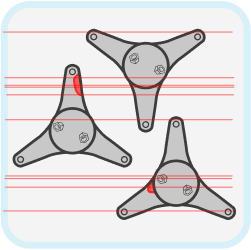

Prevent predictable anomalies and defects

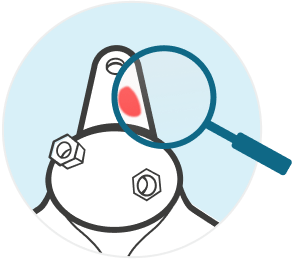

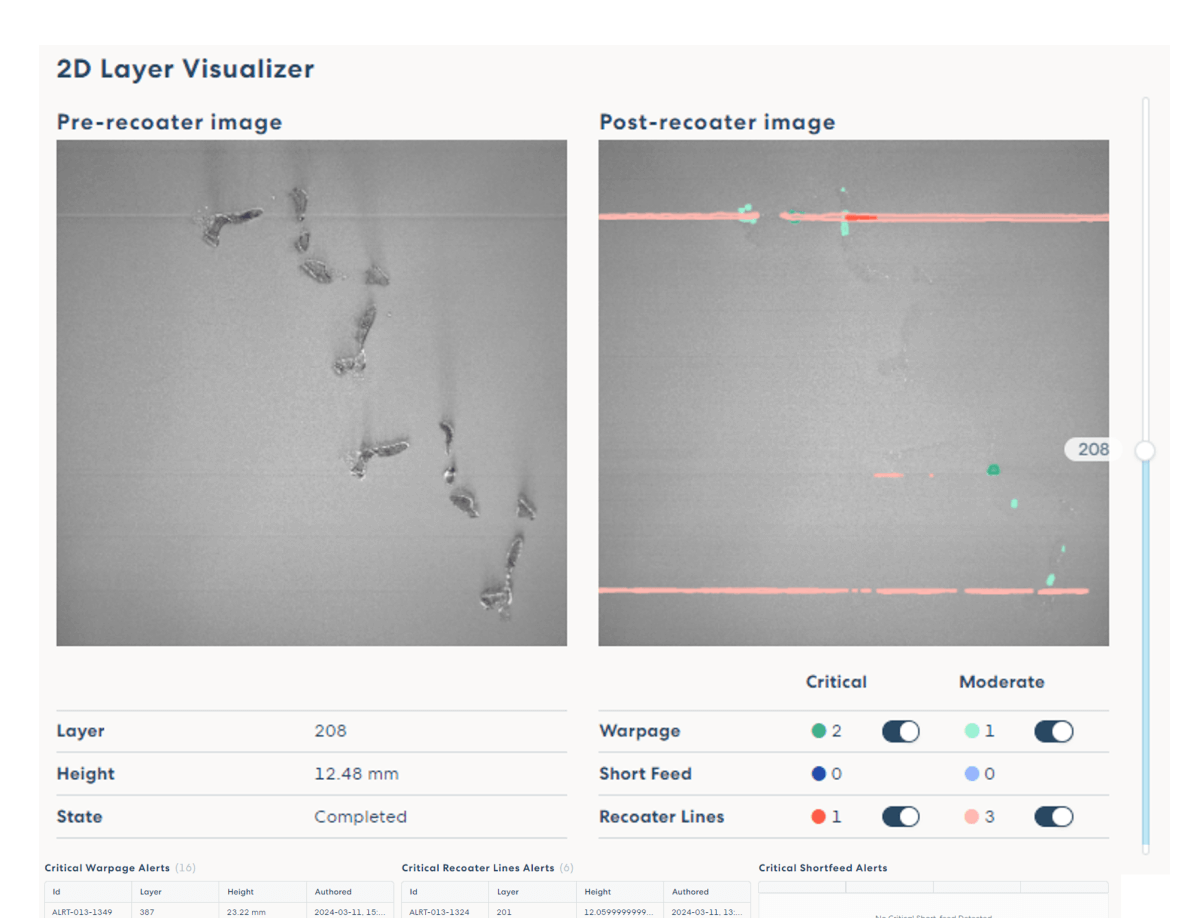

Detect anomalies in real-time

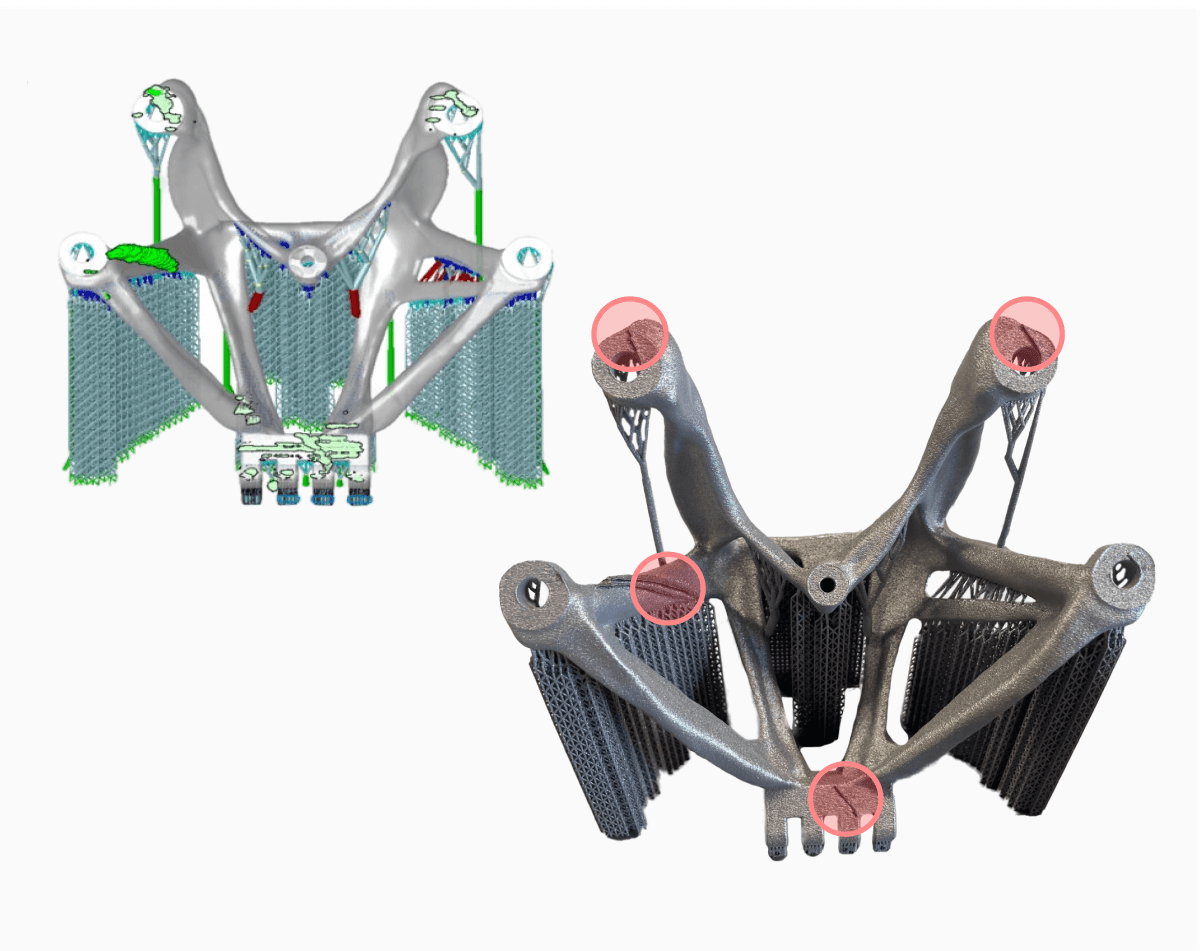

Inspect and correct anomalies and defects

Trace AM part quality. Evaluate build performance. Oqton Build Quality software ensures you meet exacting additive manufacturing quality assurance standards. Choose any combination of the following modules that can work independently or together for a fully digital metal additive quality solution:

Maximize your operational efficiency. Minimize in-field failures. Increase repeatability.

Be the leader in your industry with ground-breaking quality standards for your end-to-end additive manufacturing process.

Simulate and analyze for deformations, shrinklines, plastic deformations, thermal performance and more with 3DXpert Build Simulation.

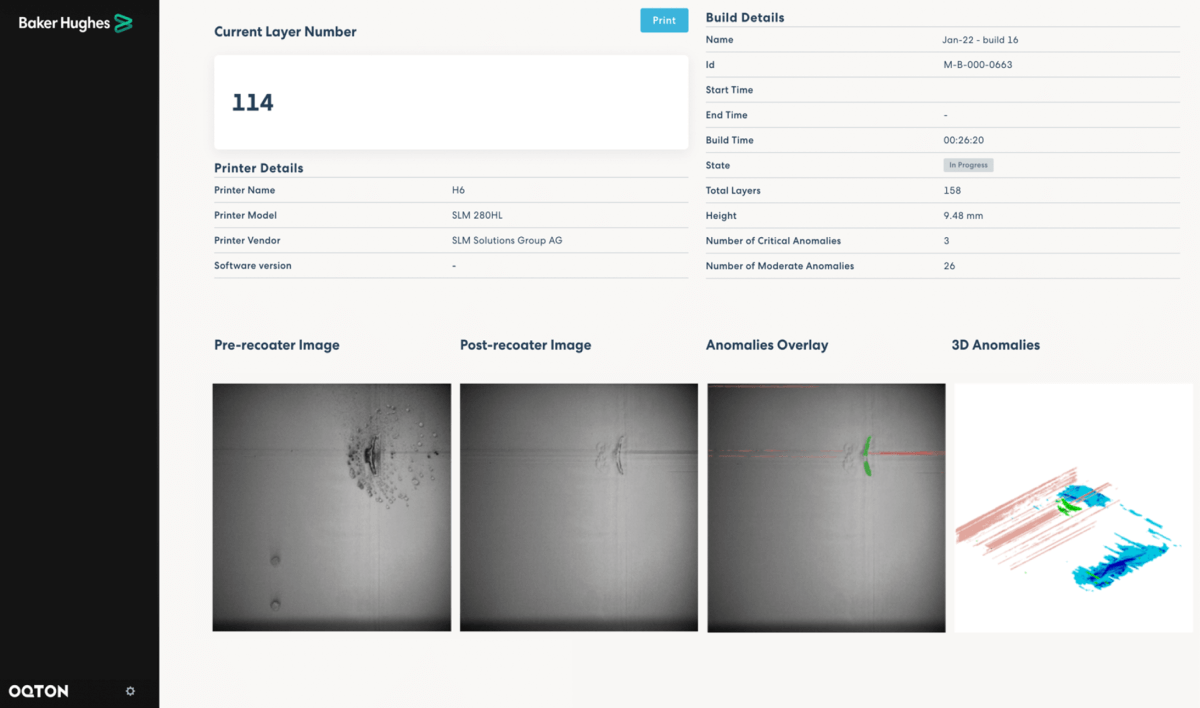

Monitor the build process in real-time using the power of AI with our cloud-based Manufacturing OS Build Monitoring.

Take fast decisions to drastically reduce scrap related costs with no extra sensors needed.

Enable remote monitoring of the machine status from your office chair or remotely from home.

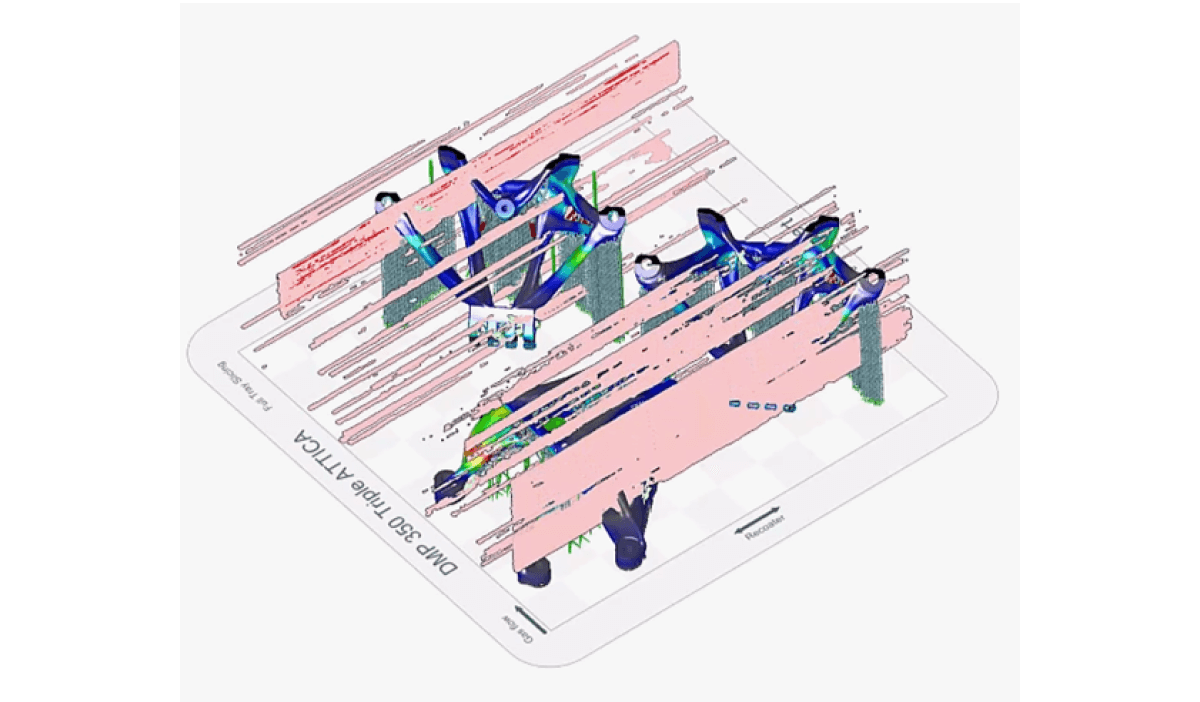

Analyze anomalies in context with the build plate with 3DXpert Build Inspection. Infer root causes, optimize & correct builds. Correlate with simulation, and scan path analyses in 3DXpert.

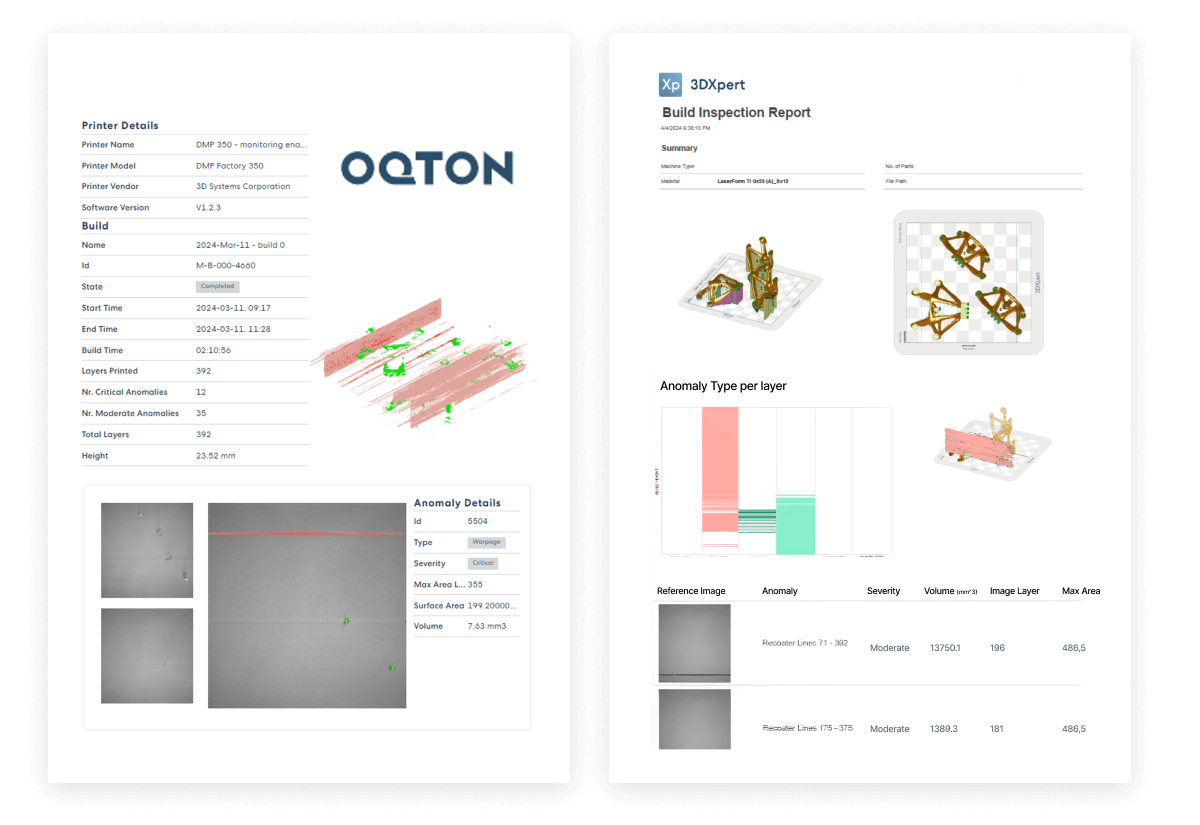

Trace the full quality process thanks to comprehensive traceability. Automatically generate detailed quality reports for each part produced.

Struggling to deliver consistent, easy-to-validate parts at scale? Successful serial production of industrial additive manufacturing parts requires an end-to-end process that reliably delivers consistent quality. It’s time to connect your real-world production with your digital world.

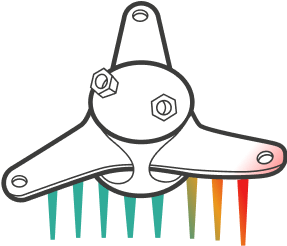

Variable Resistance Trim (VRT)

Variable Resistance Trim (VRT)VRT is vital for quality in high-pressure liquid applications. Early anomaly detection is crucial to reduce waste and maintain top-notch part quality.

Baker Hughes used Oqton Build Quality to successfully create an end-to-end process for the serial production of a Variable Resistance Trim (VRT) component.